|

|

|

| |

|

#11

|

|||

|

|||

|

There is exactly one way for a primer to back out of the primer pocket. There has to be space at the base of the brass for that to happen.

The primer gets flattened when the case is thrust rearward. The ejector mark is caused by the rearward thrust. Remember, the case is softer than the primer cup. I still think you should measure your cases. It will give you much more solid information than having us tell you our thoughts. Measure a new unfired case for headspace. Deprime only, no resizing, a fired case and compare the headspace. The new unfired case will be under specs. Merry Christmas. |

|

#12

|

|||

|

|||

|

Were I in your moccasins, the first round fired that left a primer that flat would have been the last fired from that batch! I would have dropped that down at least a full grain to re-start, if I were staying with CCI 400's.

Does a new bullet fall into the neck of a fired case? Could be a neck thickness issue. Did you happen to go back to the first batch (where the primer looked normal) and shoot any more of those? CCI 400 primers are not all that hard. Remington 7 1/2 or Federal 205/205M/GM205M seem to work without issues Hopefully you did not damage your rifle, and be thankful you did not damage any body parts doing that (coming from a fellow with one eye due to reloading stupidity long ago). |

|

#13

|

|||

|

|||

|

Back in the 80s/90s, I shot a Wichita Silhouette Pistol in competition, a .30 IHMSA. The cases were formed from either 300 Savage or .308 Winchester, and once fireformed, were always neck sized. I used mostly Winchester or Federal brass, and had one batch of 50 formed from Federal .300 Savage brass where the primers ALWAYS backed out every time they were fired. This did not happen with any other batches, no matter what the parent cases were. The ones that did back out did not shoot any better or worse than any others, always the same loads, same bullets, etc. Probably had upwards of 10 firings on them, and it happened each and every time. If there was space at the base of that brass, I'd sure like to know how it got there, and stayed there after multiple firings neck sized.

Last edited by dungheap; 12-25-2018 at 01:14 PM. Reason: typo |

|

#14

|

|||

|

|||

|

Primer backs out of the pocket? Head space issue. (not chamber issue) Case too short for chamber, goes BANG, case moves back against bolt head, primer tries to back out and gets pushed back into the pocket, case head gets slammed against bolt head causing "high pressure" marks.

Bolt problem? HELL NO! Increase the OAL of the rounds by pulling the bullets out "a bit" to hold the round against the bolt head. You're after a slight jam!! After fired, make sure you don't push the shoulders back too far and end up with the same situation. |

|

#15

|

|||

|

|||

|

I think Mikie hit on something, if your not changing the seating die from one bullet to the next and your bumping your brass back to much could very well be a headspace issue. Seat a 34 V- nightmare out just slightly into the lands and if theres no problem that will let you know your bumping your cases back and if that's the case get a case guage and start using one to me as sure your bump.

Most of the time it takes 2-3 firings to get them fully formed. |

|

#16

|

|||

|

|||

|

jimreed1948

I have a Cooper M38 chambered for the 20 VarTarg and I think you have a few problems: 1. Head space: case too short 2. Heavier brass: Remington -> Nosler 3. Heavier bullet: 32 -> 34 grains First, as many have pointed out, your case is too short so the head space is incorrect. I also think you have a pressure problem, but I'll get to that later. You didn't mention how you are forming your brass. I have a Redding 3-die set that includes a body die, a bushing neck sizer, and a seater. The body die partially reduces the neck and changes the shoulder angle, perfectly setting the head space for my chamber. Then I use a .227-inch bushing in the neck sizer and I'm done. I started with Remington 221 Fireball brass and then switched to Nosler 221 Fireball brass with no forming problems. Here's the body die: https://www.midwayusa.com/product/93...dding-body-die If you don't want to shell out for the body die, here's a tip I picked up on this forum for setting head space correctly when forming brass. I wish I could credit the person who wrote it: After you have the neck sized and you are about to start pushing back the shoulder of your first case in the full-length sizer, start with the case fully raised at the top of the stroke, then screw in the die until it contacts the case shoulder. Next, raise the press handle retracting the case a bit and screw in the die a half turn deeper and tighten the lock ring. Run the case into the die and then try to chamber it in the rifle. It probably won't go, so screw in the die another half turn deeper, run the case into the die and test it again. Repeat until the bolt starts to turn when you try to chamber the case. Now you are close. Half-turn increments on the die doesn't seem like much, but there is not much difference between the Fireball case and the VarTarg case, and you don't want to overshoot and make your head space too short. Take a piece of scotch tape and stick it to the case head, trimming the excess with a razor or a sharp knife. The tape is about .002 inch thick. Continue incrementally sizing the case until you can close the bolt with slight resistance. If you add another layer of tape, you shouldn't be able to close the bolt. Remove the tape and clean the case head with alcohol or solvent. Now you are ready to finish sizing the rest of your cases. That takes care of the head space problem. I think you also have a pressure problem because the edge of the primers are blowing out when the primer backs out. You don't say where you got your load data, but I assume you found it on the forum or elsewhere on the internet. Two problems: your loads may be a bit hot because I don't think anyone other than Western Powders has pressure tested data for the 20 VarTarg, and the data from wildcatters and Western Powders was developed using Remington 221 Fireball brass. But you are using Nosler 221 Fireball brass. When I switched from Remington 221 Fireball brass to Nosler 221 Fireball brass, I weighed some cases from each brand and found the Nosler brass averaged 1.71 grains heavier than the Remington stuff. That works out to a 2.1% difference. So the Nosler brass is thicker and has slightly less internal capacity. Not much, really, but we are dealing with small cases and small powder charges, so small changes can have a large effect. I use A-1680 in my rifle, although Western doesn't list it anymore, having replaced it with A-2200 in their published data. Western Powders A-1680 data using the Sierra 32 gr. BlitzKing, WSR primers, and Remington brass in a 24-inch barrel is Start 16.6 gr. 3437 fps Max 18.5 gr. 3793 fps Using the same components, I worked up from 16.9 to 18.5 grains in .2 grain increments. From the 22-inch barrel of my Cooper M38, at 18.5 grains I got 3690 fps and my best group at .321 inch. When I switched to Nosler brass, I also switched to the Hornady 32 gr. V-Max. I should have changed one component at a time, but I was taking the rifle to South Africa the next day. Yes, I am a procrastinator.  I reduced Western's data by 2.1% and came up with Start 16.2 gr. Max 18.1 gr. At the range I tested from 17.5 to 18.1 grains in .2 grain increments. 17.9 grains gave me 3691 fps, a group size of .266, and nicely rounded primer edges. 18.1 grains was close to the same velocity and primers still looked good. I had loaded a couple rounds each of 18.3 and 18.5 just to see what happened. Velocity still failed to increase much and primers were just starting to flatten a bit. So I think 17.9 is the max for that combo in Nosler brass, and maybe a bit hot since velocity didn't increase much after that. If you pick a cartridge in a loading manual, for a given powder, as bullet weight increases, maximum powder charge decreases. That's because the heavier bullets are not moving as fast as the lighter bullets, but the powder is burning at the same rate, producing gas and pressure at the same rate. I noticed that when you switched from a 32 grain bullet to a 34 grain bullet, you increased the powder charge. It looks like that's when the primers that were backing out from the short head space also began blowing from what I believe is excess pressure. I think the pressure problem is caused by a combination of two things: 1. Using data that might be a bit hot in Remington brass and not reducing the powder charges for the heavier Nosler brass. 2. Increasing rather than decreasing the powder charges to compensate for a heavier bullet. Going from a 32 grain to a 34 grain bullet is a 2 grain change. Looking at the Western Powders data for the 20 VarTarg, I see a roughly one grain decrease in powder charge going from a 32 to a 40 grain bullet, an 8 grain change in bullet weight. So if I changed from a 32 grain to a 34 grain bullet,I would reduce my powder charges by .25 grain to compensate for the increase in bullet weight. Wrapping it all up, subtract .4 grain of powder going from Remington to Nosler brass. Subtract .25 grain of powder going from a 32 grain to a 34 grain bullet. Starting with data using Remington brass and a 32 grain bullet, I would reduce my charges by .65 grain across the board if using Nosler brass and a 34 grain bullet. If you don't want to do the math yourself, there are calculators on the internet like this one: https://www.calculatorsoup.com/calcu...calculator.php Sorry this ran so long. Merry Christmas! |

|

#17

|

|||

|

|||

|

Thanks everyone for all the good information. I'm checking into most of the comments left. I going to send the rifle to Cooper and have them check it out before I do anything else.

I'm also in the process of replacing some of my older reloading components. Many of my tools are from the late 60's when I started. Remember when you had to have a lube pad to roll your brass on before resizing, I still have one of the originals. My Rock Chucker press is probably one of the originals made. What is one of the better case gauges? Last edited by jimreed1948; 12-26-2018 at 01:58 PM. |

|

#18

|

|||

|

|||

|

When you get your rifle back from Cooper and their findings/report. Please share what they find and recommend.

I am still sticking with the rifle being just fine, no headspace issues, Other than what you might incurred with your sizing and mostly a way over pressure load, causing the problem that developed. Time will tell when Cooper checks out your rifle and gets back to you. Bill K

|

|

#19

|

|||

|

|||

|

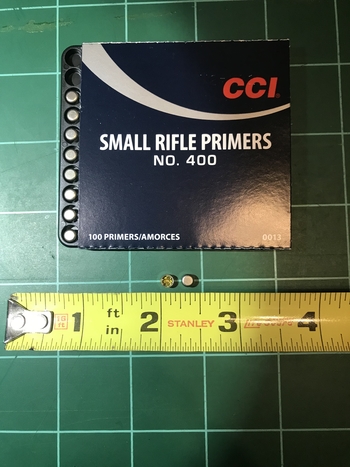

Those aren't CCI 400's, all CCI primers are nickel plated, what primers are these? None of the pics show any blanking or piercing, with a large diameter firing pin, which is typical of 50K plus PSI and the relatively thin and sensitive CCI 400.

Possible small pistol primer by mistake? Measure the wall thickness. Below .022" is BAD for a 50Kpsi plus pressure rifle case. Copper plated primer list- Winchester, PMC, Wolf/Tula/Magtech. Anybody know of others? Again, those aren't 400's. Should be using 450's, BR4's, Tula/Wolf SRM, Remmy 7 1/2's, or 205's for high pressure rifle loads. Verify what primer that is before tearing your hair out looking for causes. |

|

#20

|

|||

|

|||

|

Quote:

|

|

|

|